BMS backs $255m round for contract cell maker Cellares

Cellares has just closed a major $255 million third-round financing that will be used to complete a highly automated facility in New Jersey for the production of cell therapies.

The Series C takes the total raised to date by the California company to almost $355 million and has been led by Koch Disruptive Technologies with Bristol Myers Squibb, DFJ Growth, Willett Advisors, and existing investors Eclipse, Decheng Capital, and 8VC also contributing.

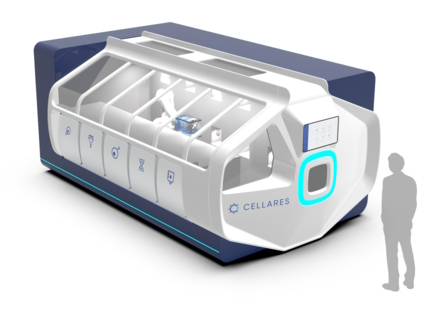

Cellares already has a facility in South San Francisco that will make extensive use of robotics and other automation technologies from its modular Cell Shuttle platform when it goes fully online in the first half of 2024.

A new facility in Bridgewater is due to be ready to start production for clients in the second half of next year and will be followed by a third plant in Europe at an as-yet unannounced location.

Ultimately, the company's goal is to improve the efficiency of cell therapy production, which often requires expensive and time-consuming manufacturing processes.

To date, the FDA has approved half a dozen CAR-T therapies, for example, but all require a complex manufacturing process that involves harvesting cells from a patient, modifying them in the lab, and culturing them in the quantities needed to be used as therapy before treatment can take place. For most CAR-Ts, that can take up to two weeks.; each Cell Shuttle module can handle 10 patient samples at a time, according to Cellares.

While other cell therapies are being developed as 'off-the-shelf' medicines, the sheer number of candidates coming through the industry pipeline means that there are some concerns about the available capacity to manufacture them affordably at scale.

There were more than 2,220 ongoing clinical trials evaluating cell and gene therapies as of 2022, according to figures (PDF) from the Alliance for Regenerative Medicine, and the FDA's Center for Biologics Evaluation and Research (CBER) has said it expects to be handling 10 to 20 reviews for cell therapies a year by 2025.

Cellares says that its new 118,000 sq. ft. facility in Bridgewater will be capable of producing 40,000 cell therapy batches per year – around 10 times more than conventional facilities at contract development and manufacturing organisations (CDMOs) that rely more heavily on manual processes – from 50 Cell Shuttle modules.

The company says that manual processes can be automated and transferred onto its Cell Shuttle platform in as little as six months.

"Cell therapies have tremendous curative potential across a wide range of diseases. But right now, manufacturing by conventional CDMOs is expensive, failure-prone, and impossible to scale," commented David Mauney, managing director of Koch.

"Cellares is driving transformation in the marketplace by combining an Industry 4.0 approach with full vertical integration."