Real world data essential for CAR-T therapy success

Developers of the new generation of CAR-T cancer therapies will likely have to generate “real world data” on top of clinical trial evidence in order to get these hugely costly products to market, an expert has said.

Novartis looks like it will get its chimeric antigen receptor T-cell (CAR-T) therapy to market ahead of rival Kite in blood cancer.

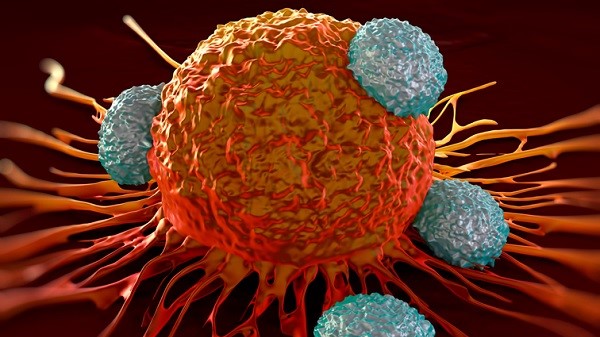

The therapy involves harvesting a patient’s own T-cells and genetically modifying them to attack cancer – a process that is difficult and costly.

On top of this, the therapy can have extreme side-effects as it can cause the immune system to go into overdrive, requiring skilled medical care to counteract the effects of so-called “cytokine storms”.

Amy Grogg, senior vice president of strategy and commercialisation at wholesaler AmerisourceBergen, told pharmaphorum in an emailed interview: “To overcome the unique barriers across both the approval process as well as coding, coverage and reimbursement, innovators must be able to prove the inherent worth of their products and demonstrate their long-term safety, efficacy and real-world cost-effectiveness.

“Innovators will need to quantify and value the healthcare resources utilised, such as doctor visits, laboratory tests, and hospitalizations, for patients on their therapies as well as the current standards of care.

“Their data strategies should also include 'hidden costs' for payers, such as those associated with managing side effects for both the new therapy and its comparator.”

The data available will decide whether manufacturers are able to achieve regulatory approval, secure payer coverage, and get patients and doctors to use the therapies once approved.

CAR-T therapies also pose a huge logistical challenge – they demand strict time, temperature, shipping and storage requirements as the modification of T-cells may well occur at a lab separate from the patient’s clinic or hospital.

This will require contingency plans to safeguard against unforeseen issues such as adverse weather conditions when shipping the T-cells to and from the lab.

Pete Belden, president of AmerisourceBergen’s logistics arm ICS, said: “In order to protect and ensure the product’s integrity, other critical services include coordinated peripheral scheduling to pinpoint pickup, real-time product tracking and temperature monitoring as well as advanced cryoshipping technologies.

“As the product moves to market, innovators should identify a partner that can provide integrated logistics.”