Are microtaggants the key to making medicines smarter?

Pharmaceutical companies are accountable for ensuring that their medicine is safe when it comes into the hands of patients. The dramatic rise in online drug sales during the COVID-19 pandemic has increased the supply of counterfeit drugs, and many companies are now considering the addition of on-dose authentication for high-risk or high-value products.

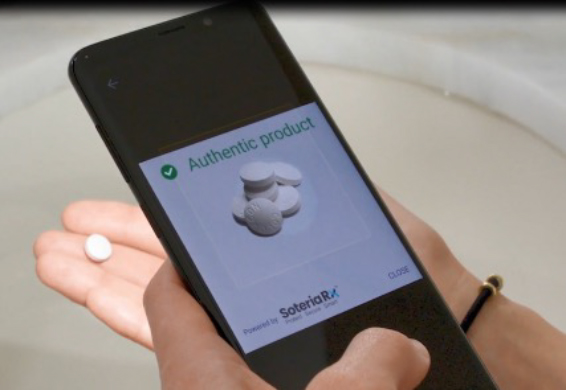

To implement on-dose authentication, microtaggants are incorporated into coatings or inks used on each tablet or capsule; these can then be verified using desk-top readers or handheld devices, such as smartphones. This innovative solution doesn’t just provide the most robust method currently available for verifying drugs. Proof of concept shows that it is possible to identify microtaggants using smartphone apps, leading the way to software development kits (SDKs) which can be customised for individual companies and products.

For example, an app could remind a patient to take their medication, scan the tablet product to verify that the right medicine is being taken at the right time, deliver alerts and patient information, and indicate when repeat prescriptions are needed. Specific apps could also alert healthcare providers if vulnerable patients are failing to scan their medicine. This technology can also play an important role in supporting virtual clinical trials.

The threat of illegal online pharmacies

Globalisation and outsourcing have led to complex supply chains for many pharmaceutical products. This increases the risk of counterfeiting and diversion, which can result in health risks and loss of trust for the consumer, and loss of revenue and reputational damage to the brand owner.

Many countries have introduced serialisation legislation which requires product identifiers to be affixed to each package to provide traceability throughout the distribution supply chain. However, traceability and security measures focused on the packaging level may not be enough to protect patients. Even if a package is authentic, it may be impossible to determine whether the medicine inside is real or fake and whether it has been diverted.

It is estimated that the incidence of counterfeiting, illegal diversion and theft in the US increased by almost 70% between 2015 and 2019 driven mainly by a rise in internet sales. According to the Alliance for Safe Online Pharmacies, 100% of online searches to buy medicine return links for illegal pharmacies, and in 2018 the US Food and Drug Administration estimated that only 3% of online pharmacies complied with US pharmacy laws and practice standards.

Since the start of the COVID-19 pandemic, there has been a significant increase in online drug sales, and 1 in 4 American consumers now buy their medicines online. This had led to a corresponding rise in the supply of counterfeit drugs. The widespread use of pill presses by criminal gangs means that they can change production and ingredients rapidly to satisfy market demand. While counterfeiters often target lifestyle drugs, every medicine is vulnerable to counterfeiting and life-saving medicines are the fastest-growing category.

In 2020, the World Health Organization reported that over half of all drugs purchased from online pharmacies are suspected counterfeit, and identified the issue of counterfeit drugs as one of the urgent health challenges for the next decade. Writing in the American Journal of Tropical Medicine and Hygiene in 2019, doctors from the US government, universities, hospitals and the pharmaceutical company Pfizer warned that the rise in “falsified and substandard medicines” has become a “public health emergency” and that poor quality drugs exact an annual economic toll of up to US$200 billion. In addition to the direct harm that they cause, the supply of counterfeit antibiotics is a major driver of antimicrobial resistance.

There is growing recognition that serialisation alone will not solve the problem of counterfeit medicines. As serialisation matures it will provide a valuable tool for track and trace, but for the highest risk products, on-dose microtaggants provide a much higher level of security as each tablet or capsule can be authenticated. Instant verification at the dosage level reduces the risk of counterfeiting and product diversion while facilitating quality control and returns monitoring.

Microtaggants are uniquely encoded materials that are virtually impossible to replicate or reverse engineer. They can be incorporated into tablet coatings, or into the inks used on tablets or capsules, and detected using either field or lab-based equipment.

The technology requires no additional manufacturing equipment or processes, which makes it cost-effective and easy to implement. The FDA has stated that when microtaggants are pharmaceutically inactive and incorporated into new or existing drugs, they can be treated as excipients without the need for further clinical trials. Therefore, manufacturers of an approved product in the US would only need to incorporate the microtaggants as a Level 1 post-approval change in the Annual Report.

Two different types of microtaggants are now available, one produced from non-biologic DNA and the other from silica:

DNA microtaggants

DNA is robust and easy to detect and because it is possible to produce different versions of the same DNA molecule, it can be made regional, product, or company-specific. The microtaggants are simply added to the standard tablet film coating or capsule printing process and can then be detected using appropriate reagents (like lock and key). The microtaggants are not damaged by exposure to heat and pressure during manufacturing, and the integrity of the DNA remains consistent throughout the shelf life of the product.

Silica microtaggants

Spectrally encoded silica microtaggants can be detected by how they reflect light and can be customised with unique information for product verification and traceability. Like DNA, the microtaggants are incorporated into the film coating or printing ink and applied during the manufacturing process. Silica is already present in virtually all tablet and capsule formulations, making it an easy material to include.

Recent work has concentrated on developing convenient readers to scan information carried on the microtaggants. Proof of concept demonstrates that tablets or capsules with silica microtaggants can be identified using smartphone apps, providing instant verification by law enforcement and border agencies.

The introduction of smartphone apps means that patients could play a part in verifying their medication, and that interaction could be leveraged to add value through patient engagement and brand loyalty. Through software development kits (SDKs) this type of app can easily be customised for individual companies and specific medications to help:

- Improve adherence and achieve better outcomes for patients

It is easy for someone who is sick or confused to take the wrong drugs or miss doses. The app can remind patients when it is time to take their medication and which tablets to take. For many conditions, for example following an organ transplant or for the treatment of certain cancers, adherence to the correct medication regime is vital. Scanning each tablet before it is taken would reassure the patient, and results could also be relayed to a caregiver or medical team, alerting them if the patient has failed to scan the medication at the correct time. This could also be helpful in the case of people living with early-stage dementia.

- Promote patient trust and brand loyalty

Cases have been reported of patients with extremely serious conditions failing to take their medication due to concerns over side effects. The app could remind and actively assist patients to recognise certain side effects, provide reassurance that they are not unusual, and help manage these initial challenges to ensure they stay compliant with their regimen. There could also be reminders for repeat prescriptions, and updates as new information becomes available. This type of engagement could give the patient a sense that the drug manufacturer is doing all it can to support them.

- Make virtual clinical trials more robust and reduce costs

Virtual clinical trials could help to recruit more patients and greatly reduce R&D costs. The COVID pandemic has brought this a step closer but trials must be robust. It may be soon possible for patients to film themselves scanning and taking a drug as required for the trial, thus improving visibility and compliance, and providing real-time patient support.

- Reduce wastage

Medicine waste can occur due to patients over-ordering medicines on repeat prescriptions or continuing to order medicines which they no longer take. In 2010 a report from the Department of Health estimated that unused medicine costs the NHS in England around £300 million each year. These figures don’t take account of the impact on patients’ health if medicines are not being correctly taken, which could lead to worsening symptoms and further treatments that could have been avoided.

Choosing the best solution

It is important to understand how effective and reliable an authentication process will be, and the benefits that may be gained as a trade-off for the time and resources required to implement advanced technology.

This technology equips product quality teams with a faster way to identify rogue batches and make more informed decisions as to whether a batch needs to be held pending further investigation or immediately recalled. The cost per tablet of incorporating microtaggants is negligible relative to other manufacturing costs and the overall cost to the producer of the finished dosage form. The quantities of microtaggants that are added to the film coatings or inks are small, and their use has no impact on how coatings are applied, and will not affect the product’s stability, disintegration or dissolution. Machine-reading of security features is faster and more reliable than manual inspections and will be suitable for high-volume applications.

Through real-time data collection and analysis, patient-focused product teams will be able to provide more personalised support resources at the right time. Incorporating microtaggants directly into the product and associating the smartphone app provides a unique opportunity for brands to interact with patients as they are taking their medication to ensure the best possible outcomes. The app could be used to offer patients improved regimen support with personalised dosing schedule reminders, regimen/therapy/condition education, copay program availability, and refill reminders.

As we look to the future, smart medicines are becoming a reality. Innovative technology can ensure digital authentication of patient's medicine using their smartphone and a secure cloud application to provide real-time support.

About the author

Colorcon designs and develops specialty excipients for solid oral dosages for the pharmaceutical and nutritional industries.