Japanese drugmakers make greener packaging pledge

Four Japanese drugmakers – Astellas, Eisai, Daiichi Sankyo, and Takeda – have joined forces in a partnership intended to reduce the environmental impact of pharmaceutical packaging.

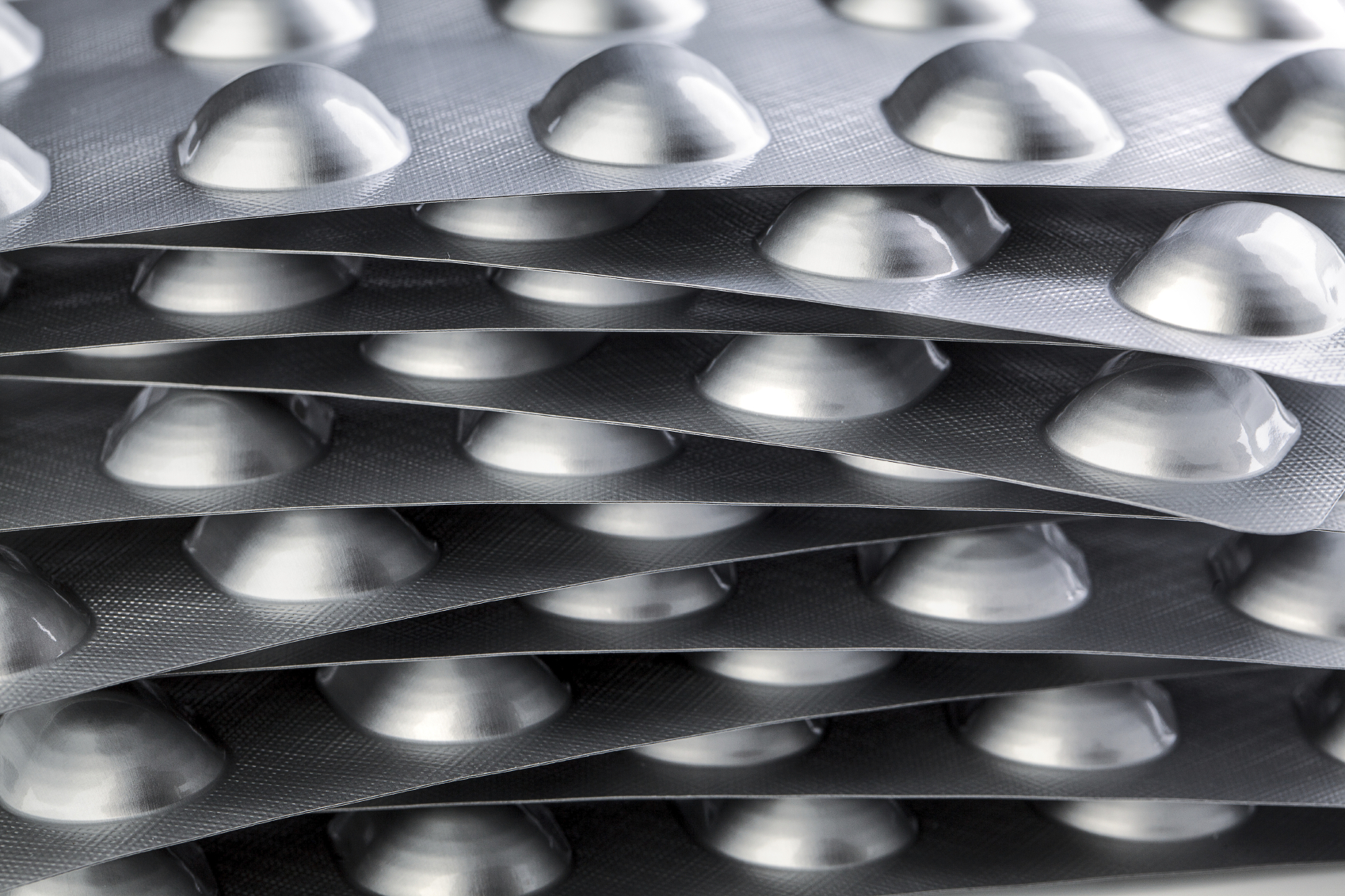

The companies say they will promote the use of greener packaging for their products by sharing knowledge on technologies that can reduce their environmental impact, including blister packs made of biomass- rather than petroleum-derived plastics and more compact packaging, as well as recycled and recyclable materials.

The collaboration comes as the pharma industry is increasingly having to face up to its impact on the environment, after years of avoiding scrutiny of its impact as a major manufacturer of goods.

A Forbes report published last year in the wake of the COP26 UN climate negotiations estimated that the 15 largest pharma manufacturers emitted 55% more carbon dioxide equivalents per million dollars of revenue than the automotive sector in 2015.

While there are big differences between companies, studies have suggested that the industry as a whole would need to a cut emissions by 59% from 2015 levels to meet the goals laid out in the Paris agreement of the same year.

Meanwhile, pharma products also generate non-degradable waste materials – known as environmentally persistent pharmaceutical pollutants (EPPPs) – with biological activity that is known to adversely affect ecosystems.

Astellas, Eisai, Daiichi Sankyo, and Takeda said their new initiative aims to ensure that "society benefits from this collaboration to harmonise corporate activities with the global environment." They also hope to recruit other companies to the collaboration in order to broaden its impact.

Among measures already being explored by the pharma industry is the development of recyclable and biodegradeable plastics derived from sugarcane – a concept developed by Natupharma – which has already been adopted by some drugmakers, including Astellas.

Last year, the company reported that it had begun using sugarcane-derived polyethylene (PE) as 50% of the raw material used in blister packaging, saying it was the world's first widespread use of the material in commercial products.

It started using the sugarcane in its irritable bowel syndrome (IBS) drug Irribow (ramosetron), sold in Japan.

Other developments across the industry include greater use of aluminium foil as a 100% recyclable material, the elimination of secondary packaging for solid-dose drugs in glass containers, and the move towards digital package inserts.